It all can start with a simple sketch.

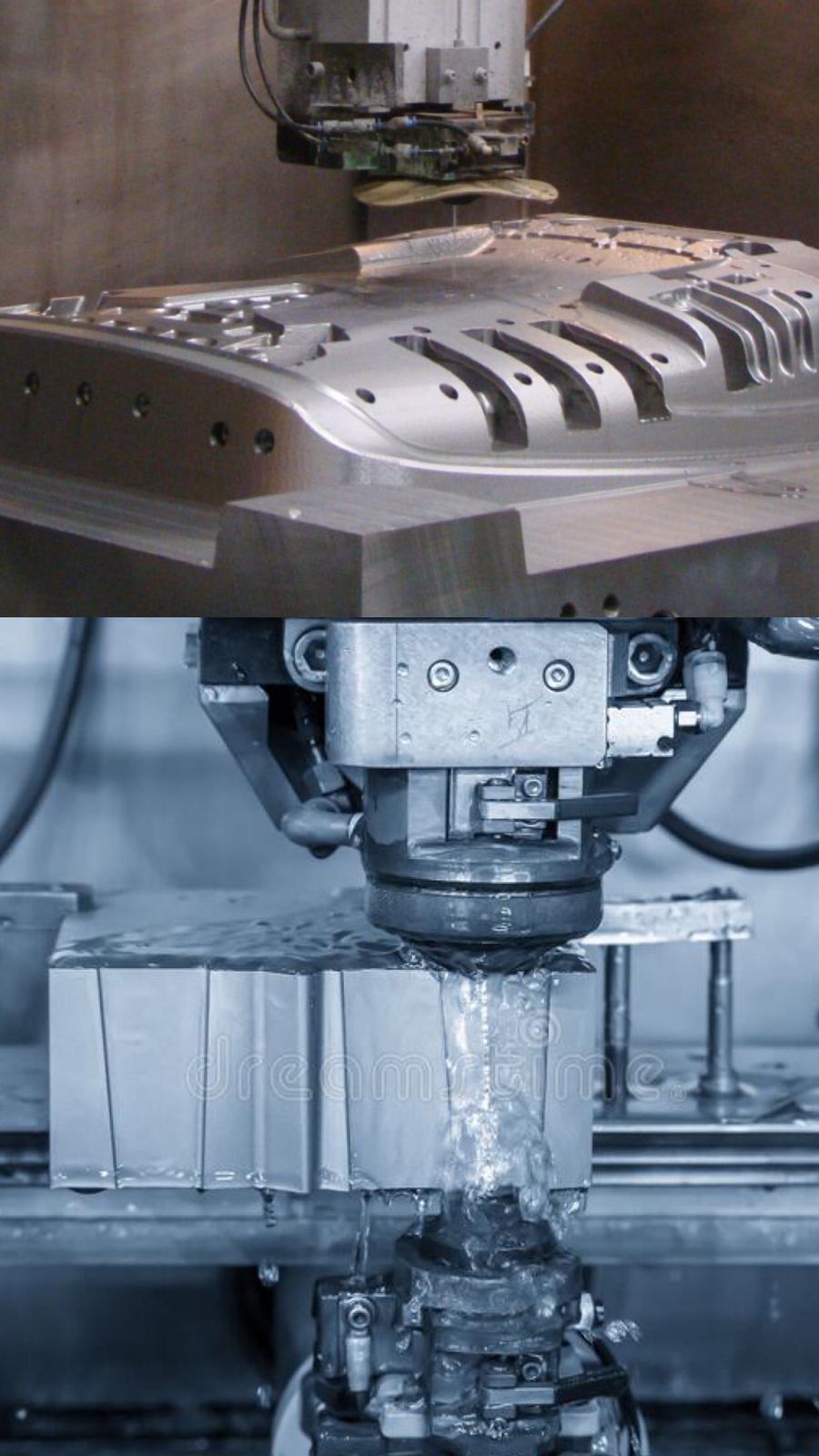

Our team of experts will get to work imputing your design into the computer with powerful CAD software.

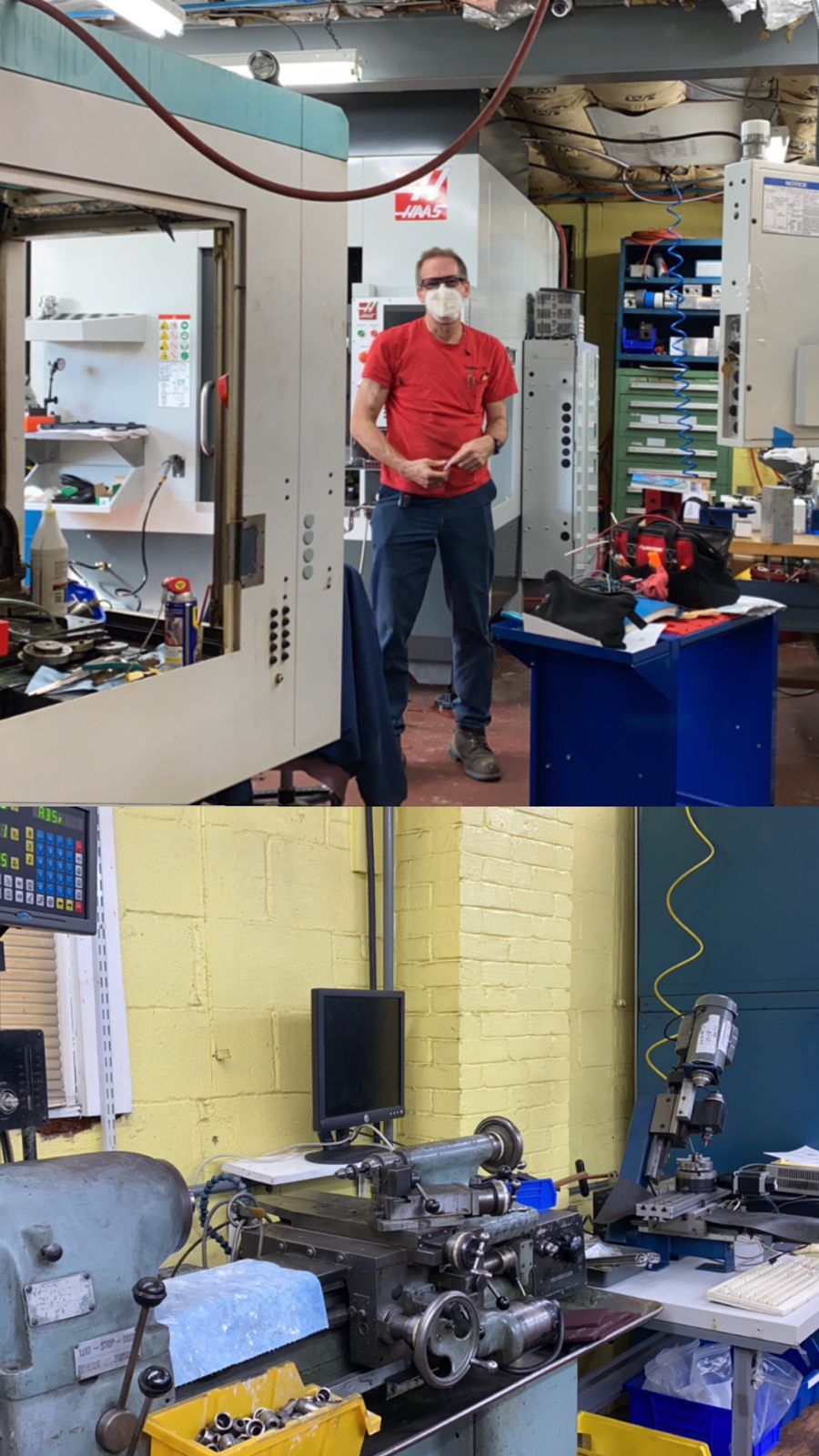

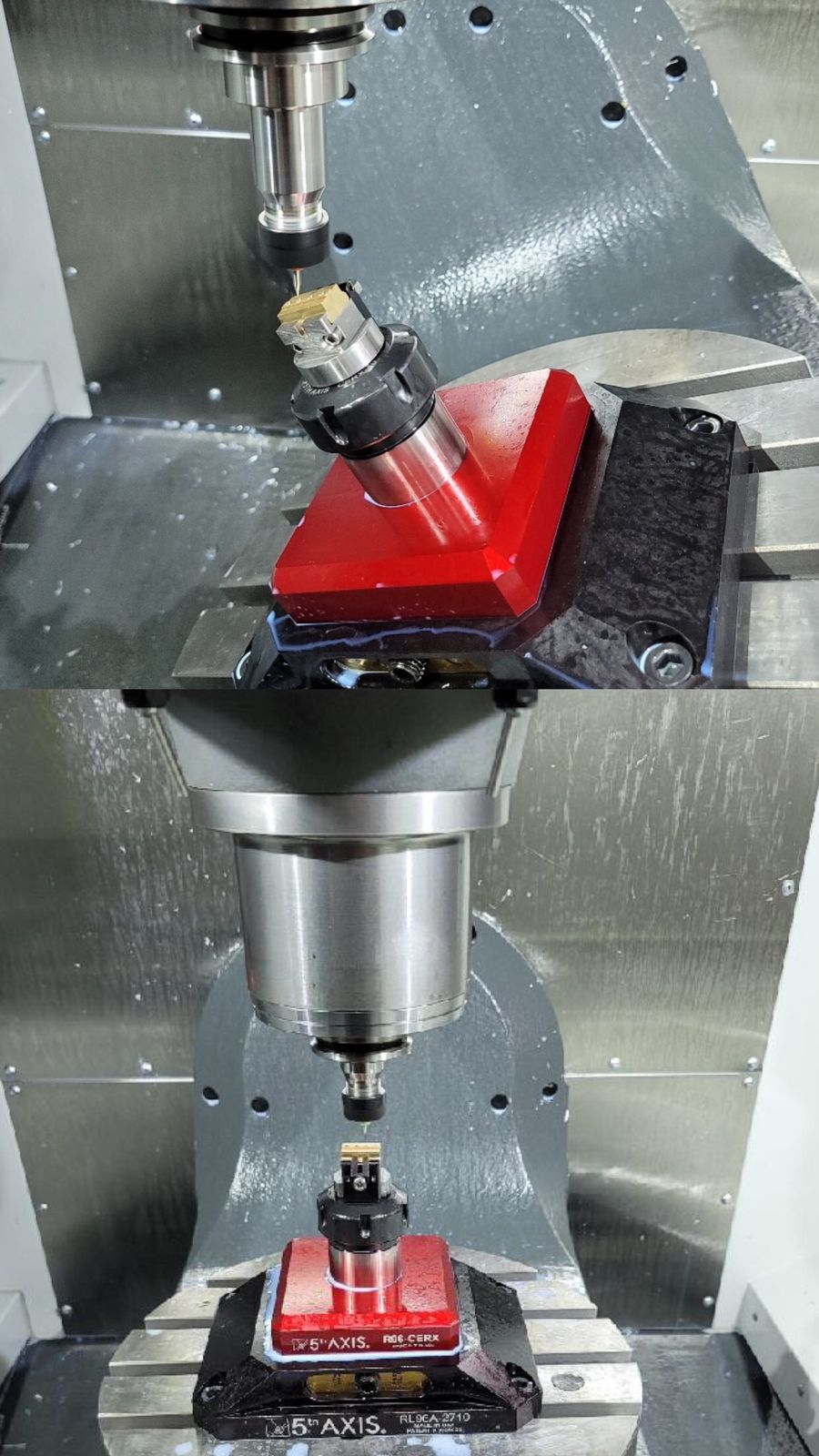

Our team of expert machinists will build you a prototype to spec.

We can then ramp up production on your final product.